| Cat. No. | Introduction | Obsolescent | Obsolete | Remarks |

| Section C.1 B.D.0600 | L. of C. 16217 84/V/852 26th November, 1912 | MN/143/011 7th March, 1968 |

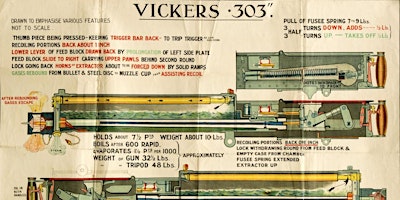

- Cat No. C1/BD 0600, List of changes 22675, GUNS, Machine, Vickers, .303-in., Mk. 1 – With dial sight bracket

- Cat No. C1/BD 7930, List of changes 22675, GUNS, Machine, Vickers, .303-in., Mk. 1 – without dial sight bracket

Training variants on the training accessories page.

Data summary

| Method of Feed | Fabric belt from right side |

| Belt | Capacity – 250 rounds. |

| Construction – canvas with brass separating strips | |

| Weight | Empty – 30 lbs. |

| With water – 40 lbs. (approx.) | |

| Length | 3 ft., 7½ in. |

| Barrel | Length – 28.4 in. |

| Calibre – .303-in. | |

| Rifling – number of grooves – 5; twist – 1 turn in 10 in.; direction – to the left; depth – .005 in. to .008 in.; width of lands – .0936 in. | |

| Sights | Type – aperture and blade. |

| Range adjustment – using Plate, Graduated, Tangent Sight, No. 2 Mk. 1 for Mk. 7 ammunition – 100 to 2900 yd. | |

| Range adjustment – using Plate, Graduated, Tangent Sight, No. 2 Mk. 2 for Mk. 8z ammunition – 100 to 3700 yd. | |

| Sight base – (radius) – 36 in. (approx.) | |

| Cyclic rate of fire | 450 to 550 rounds per minute. |

| Method of breech locking | Toggle joint. |

| System of operation | Recoil, gas assisted. |

| Change lever | Nil – full automatic only. |

| Type of cooling | Liquid cooling |

| Capacity of barrel casing | 7 pints (approx.) |

| Number of rounds required to boil water | 600 (continuous firing) |

| Rate of evaporation | 1.5 pints per 1000 rounds |

| Ammunition | Cartridges, S.A. Ball, .303 in., Mk. 7, Mk. 7z or Mk. 8z, or Tracer or A.P. |

Before the Great War

The Vickers first began service as the ‘Mk. I’ from the 26th November, 1912. This was the service pattern gun that remained largely unchanged for its entire service life. It was, by far, the largest Mark produced and the majority of parts in other Marks came from it.

The Great War

At the start of the Great War, the Vickers Mk. I in production varied only slightly from that adopted in 1912. However, it soon began to change. For the first few years, these changes were small and affected component parts and the amount of lightening that took place on that gun – the increased lightening increasing production time and cost. The completely lightened guns have a ‘five-arch’ top cover and any area where the thickness of the metal was greater than required, it was milled out so that only the minimum would remain. This even went to the extent of boring the centres of pins so they were hollow and saved precious-few ounces. The gun shown was produced in May, 1915, and displays all of the early milling.

More information on the early ‘L’ series production guns can be found in our YouTube video:

As the demand for machine guns increased even more, it was decided that a smooth barrel jacket could be produced quicker that the fluted jackets. Therefore, from late-1917 some Vickers MGs were manufactured with smooth barrel jackets. They are similar in appearance to the Second World War production guns.

Between the Wars

The large numbers of guns produced during the Great War satisfied the appetite for replacements and, with refurbishment, were able to keep the British Army equipped throughout this period.

However, with the increased mobilisation in the 1930s, it was necessary for the War Office to start placing orders for further refurbishment and the commencement of further production. All were in .303-inch.

| Date | Item | Maker | Quantity and Other Details |

| 24.04.1935 | Vickers Mk I overhaul and repair | Enfield | 100 |

| 13.06.1935 | Vickers Mk I | Vickers Armstrong | 200 |

| 13.06.1935 | Vickers Mk I overhaul and repair | Enfield | 450 |

| 29.10.1935 | Overhaul Vickers Mk I to “S” or “SM” standard | Enfield | 110 |

| 16.04.1936 | Vickers Mk I repair | Enfield | 110 |

| 06.07.1936 | Vickers Mk I repair | Enfield | 500 |

| 29.09.1936 | Vickers converted from Mk I to Mk VI | Enfield | 8 for Iraq |

| 16.06.1937 | Vickers Mk I repair | Enfield | 500 |

| 24.11.1937 | Conversion of Vickers Mk I to Mk VI LH feed | Enfield | 200 |

| 29.12.1937 | Vickers Mk I repair | Enfield | 28 |

| 05.05.1938 | Vickers Mk I repair and Mk VI conversion | Enfield | 500 |

| 08.09.1938 | Vickers Mk I | Vickers Armstrong | 200 |

| 28.03.1939 | Vickers Mk I | Vickers Armstrong | 30 |

| 11.05.1939 | Vickers Mk I repair | Enfield | 500 |

| 01.08.1939 | Vickers Mk I repair | Enfield | 200 |

Australian production

It was also during the inter-war period that Australia began to manufacture Vickers MGs at its Small Arms Factory, Lithgow.

The Second World War

The ramp-up of Vickers MG repair and production increased with the outbreak of the War. From this time, some orders placed were referred to as ‘Ground Pattern’ guns, presumably to avoid confusion with Vickers Gas Operated Mk I guns. All were in .303-inch unless otherwise mentioned.

| Date | Item | Maker | Quantity and Other Details |

| 15.12.1939 | Vickers Mk I Ground Pattern | Vickers Armstrong | 600 at £118/10/- each |

| 15.12.1939 | Vickers Mk I Ground Pattern | Vickers Armstrong | 320 |

| 18.12.1939 | Vickers Mk I repair | Enfield | 3,000 |

| 12.02.1940 | Vickers MG 7.92mm | supplied by Edgar Grimaud | 750 for Turkey |

| 16.04.1940 | Vickers MG | supplied by Edgar Grimaud | 326 |

| 09.07.1940 | Vickers Mk I Ground Pattern | Vickers Armstrong | 49 |

| 14.10.1940 | Vickers Mk I Ground Pattern | Vickers Armstrong | 920 |

| 11.05.1941 | Vickers Mk I Ground Pattern, Class “C” | Vickers Armstrong | 133, differs slightly from service pattern |

| 11.05.1941 | Vickers Mk I Ground Pattern Land Service | Vickers Armstrong | 16 |

| 12.06.1941 | Vickers MG | Vickers Armstrong | 2,000 |

| 26.07.1941 | Vickers MG | Vickers Armstrong | 1,888 |

| 07.08.1941 | Vickers MG | Vickers Armstrong | 500 |

| 10.03.1942 | Vickers MG | Vickers Armstrong | 190 |

| 13.07.1942 | Vickers Mk I w/Tripods | 2,900 | |

| 04.01.1944 | Vickers MG | Vickers Armstrong | 3,000 |

There were no more orders placed after this period. It is assumed that repairs were being carried out by the Royal Electrical and Mechanical Engineers or being scrapped. No more Vickers MGs were produced in the UK. Production did continue to take place in Australia for a short time.

Post-Second World War

In 1968, the Vickers Mk. I was declared obsolete and removed from British Army service. It was such a momentous occasion that it warranted a special dinner and an article on the front page of The Times on January 09, 1968.